| Model | Sanitary Diaphragm Seal Pressure Gauge |

| Applications | 1,Hygienic pressure measurement in sanitary applications for the food and beverage industry. 2,For gases, vapour; liquid, pasty, powdery and crystallizing media. 3,Quick cleaning, without residue. 4, Clamp connection easy to open for cleaning and seal replacement |

| Size(mm) | From 63mm to 160mm |

| Nominal size | From 2.5”to 6” |

| Scale ranges: | 0-40MpaBar, Psi, KG/CM2 pressure unit(optional) |

| Accuracy | 1.6% for 2.5” 1.0% for 4” 6” |

| Connection | 1/4” for Φ2.5” Φ4” 1/2” for Φ4”Φ6” |

| Thread Type | NPT, BSP, PT |

| Wetted parts | 304 stainless steel (316 stainless steel optional) |

| Case&Bezel Material | 304 stainless steel (316 stainless steel optional) |

| Diaphragm Seal | 304 Stainless Steel, 316 Stainless steel |

| Window | Tempered Glass, Safety Glass, pc |

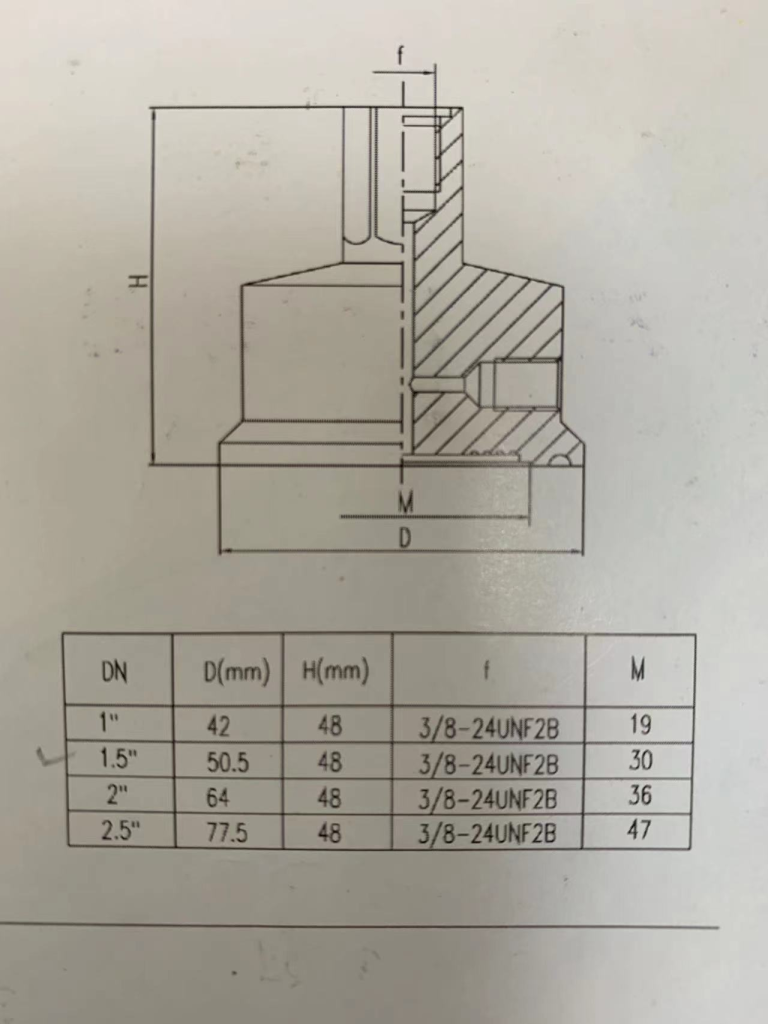

| Diaphragm | Tri-clamp, DIN, IDF, SMS, RJT |

| Pointer/Dial | Aluminum Finished |

| Operating Temperature | -4 F to 140 F(-20℃ to 60℃) |

| Media Temperature | -40℃ – 200℃(not filled) |

| Filling | Glycerine oil or silicone oil |

| Pressure Limitation | Steady:75% of scale value Fluctuating: 65% of full scale value Short time:100% of full scale value |

Uses of diaphragm seal pressure gauges

Measuring low and medium pressure: Diaphragm pressure gauges are often used to measure low to medium pressure ranges, especially for pressure measurement of media such as gas, liquid, and steam.

Adapt to harsh environments: Since the diaphragm of the diaphragm pressure gauge can effectively prevent the erosion of the internal structure by the medium, it is suitable for pressure measurement of corrosive media.

Good sealing: It is often used in places with high sealing requirements to prevent liquid or gas leakage.

Suitable for places with high hygiene requirements: In the food, pharmaceutical, chemical and other industries, diaphragm pressure gauges have good hygiene performance.